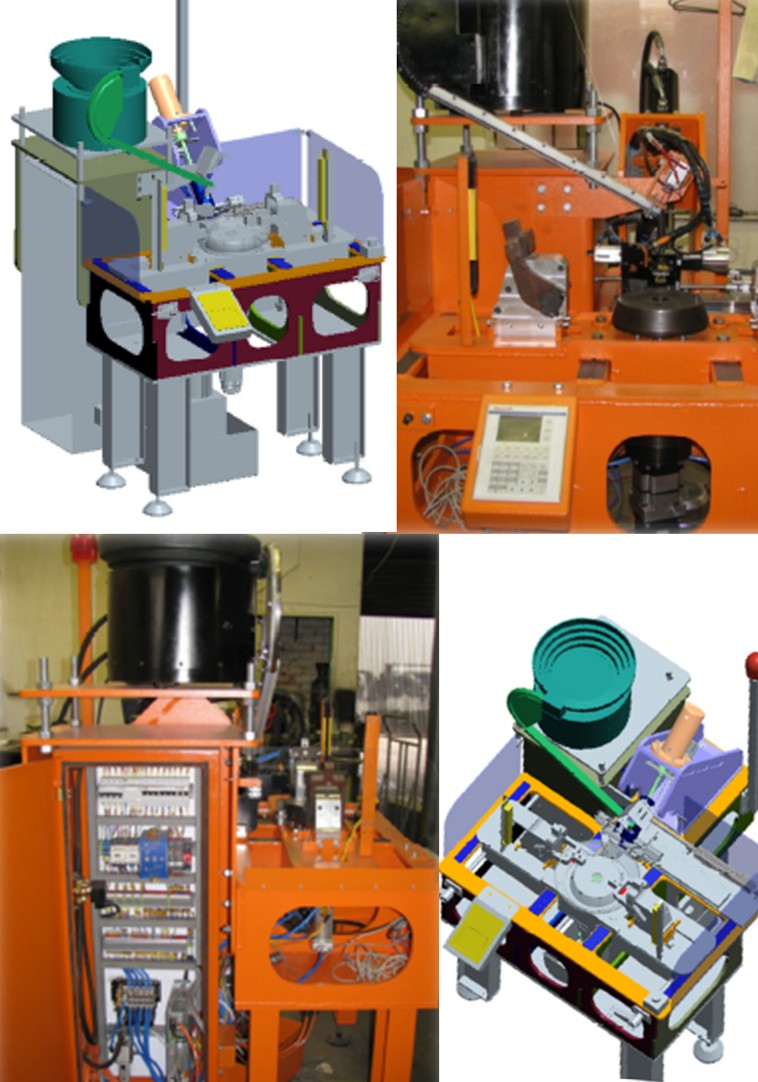

Tip Press

Project Details:

Total Value: $200 000

Year Completed: 2011

Duration: 14 months

Background:

A prototype machine was developed with plans for production within the next one to two years. To support this, additional production equipment was needed to maintain stock levels of consumable components. This turnkey project focused on developing specialized equipment to produce these consumables. MKDesigns was responsible for defining user requirements and functional specifications, progressing through the concept phase, detailed design, manufacturing, and commissioning.

Description:

The production press processes hundreds of steel tips loaded into a hopper. The tips are oriented and fed into an alignment tool, which precisely positions them for pressing into a steel housing delivered from overhead storage.