Shuttle Car Structural FEA

Project Details:

Total Value: $140 000

Year Completed: 2014

Duration: 5 months

Background:

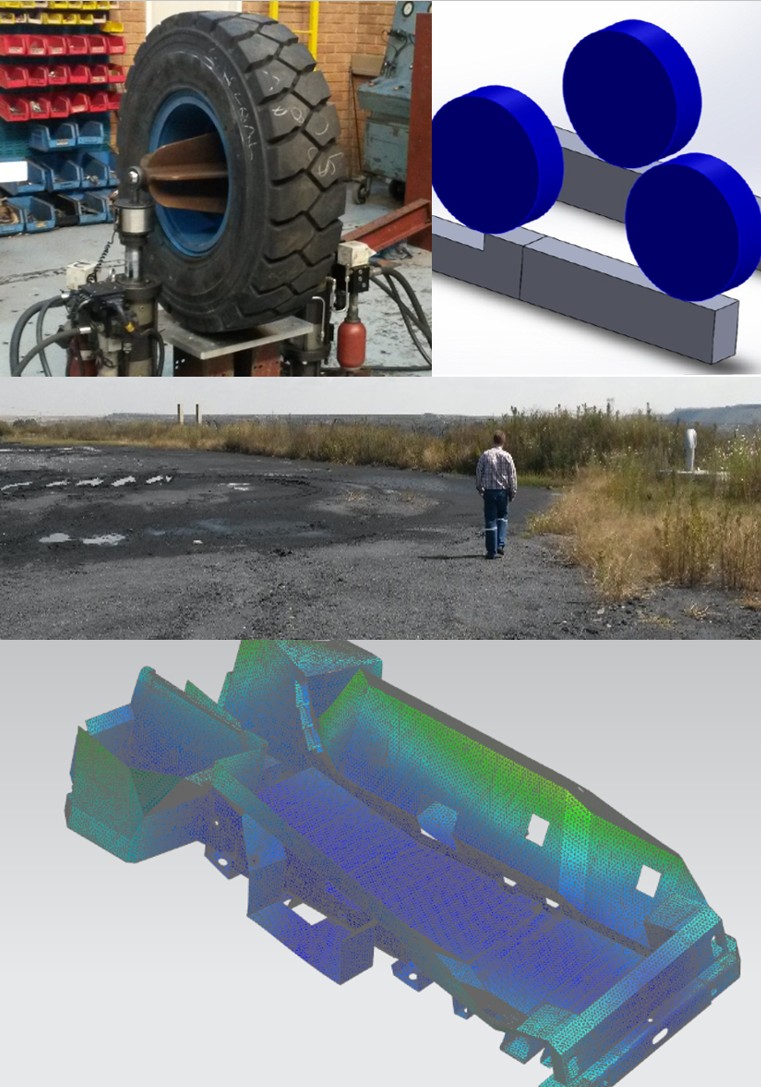

A mining company identified the need to develop a new Shuttle Car to meet future mining requirements at their facility. A new structural design and conceptual running gear layout were proposed, requiring Finite Element Analysis (FEA) and strain measurement data to validate the structural integrity of the design.

Description:

The manufacturing CAD models of the existing and proposed Shuttle Car structures were converted into FEA models with appropriate meshing. Preliminary load cases were developed to simulate potential operational scenarios. An existing Shuttle Car was instrumented with strain gauges, accelerometers, a speedometer, and displacement sensors. A test track was constructed, featuring specified obstacles and a random section to replicate underground conditions. Multiple tests were conducted by driving the Shuttle Car on the track, and the collected data was analyzed to validate both the load cases and the FEA model. Additionally, the wheels were tested separately to assess the running gear stiffness and its impact on the load cases. The verified loads were then applied to the new design to confirm the structural performance of the proposed Shuttle Car.