Ladle Turn Table

Project Details:

Total Value: $50 000

Year Completed: 2010

Duration: 3 months

Background:

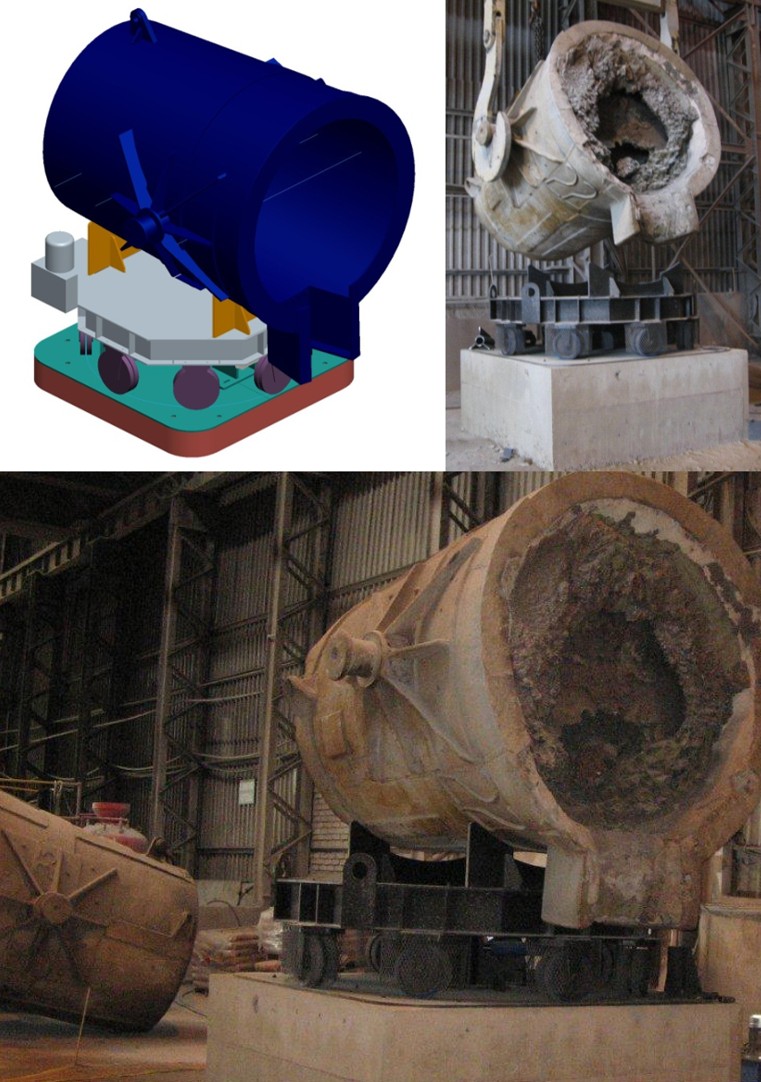

A need arose at a manufacturing facility to design, fabricate, and supply a mechanism to rotate ladles during cleaning operations. Accumulated slag inside the ladles reduced their capacity, necessitating periodic cleaning with a hydraulic hammer mounted on a tractor loader backhoe (TLB). Due to spatial constraints within the plant, rotating the ladles by 90 degrees was essential to provide adequate access for the TLB. The existing cranes were unable to rotate tilted ladles, creating the requirement for a specialized turntable solution.

Description:

A turntable capable of supporting a 20-tonne load was designed to facilitate the rotation of ladles. The project involved detailed load calculations, comprehensive design development, component selection, and specification of a hydraulic system to drive the rotation. The turntable was successfully fabricated, installed, and commissioned at the South Plant, meeting all operational requirements and improving the efficiency and safety of the ladle cleaning process.