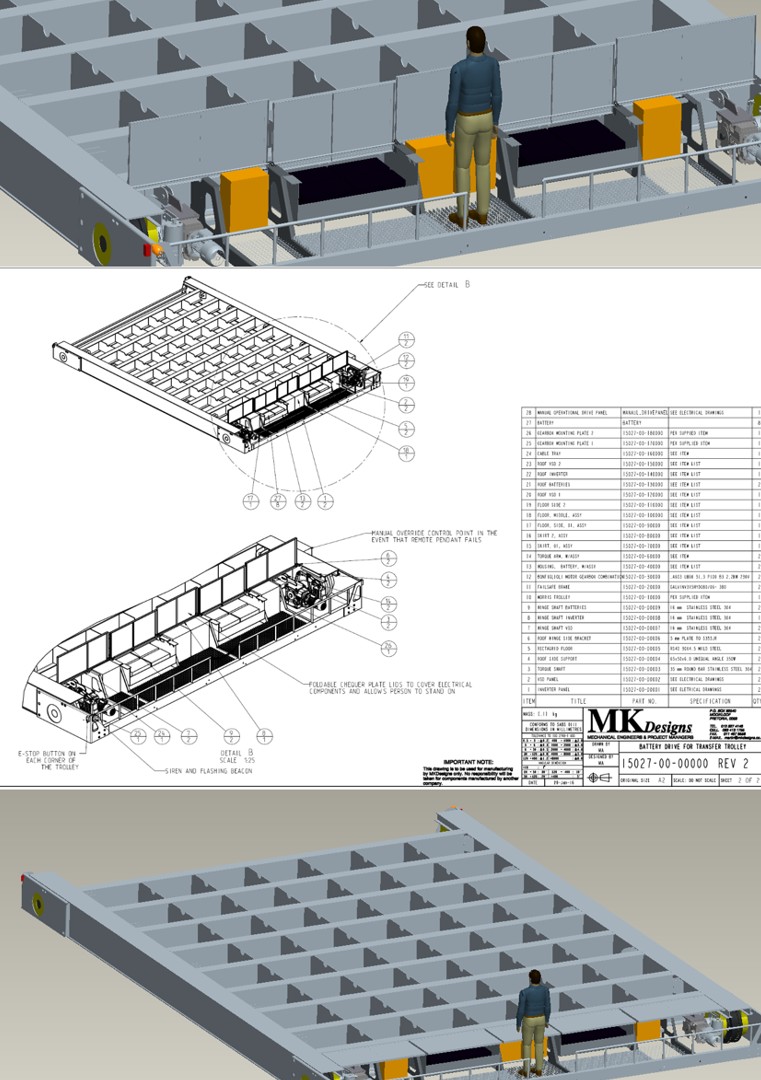

Bowl Trolley Drive System

Project Details:

Total Value: $80 000

Year Completed: 2016

Duration: 5 months

Background:

There was a need for a drive system on a trolley that is reliable, safe and free from trailing cables over a distance of 60m at a speed of 5m/min. The trolley was used for transporting a truck bowl into the boiler workshop for maintenance. The combined weight of the trolley and bowl was 75 tons.

Description:

The Mechanical System upgrade included:

- Replacement shafts on two drive wheels

- Fail to safe brake on two drive shafts

- Bonfiglioli Motor Gearbox combination (with brake on motor) on two drive shafts

- Mounts for Inverter Panels

- Mounts for VSD Panels

- Battery Housing

- Skirt on Drive-End & Non-Drive-End

- Protective Cover/s over Drive System

The Electrical System included:

- Battery Pack & Wiring

- Two Inverter Panels

- Two VSD Panels

- Two E-Stop Buttons mounted on the drive and non-drive ends

- Four Flashing Strobe Lights mounted on the drive and non-drive ends

- Infrared sensors mounted on the drive and non-drive ends

- Battery Isolator Switch

- Remote Control