Ash Handling Pumps

Project Details:

Total Value: $20 000

Year Completed: 2005

Duration: 5 months

Background:

The project was undertaken to restore Camden Power Station to operational status to meet future power capacity demands. The ash handling system required upgrading to manage ash from the boiler ash hopper and precipitator hoppers, which is sluiced to the ash sump. From there, ash is pumped to the ash dam using a newly designed two-stage pumping arrangement, with pumps coupled in series. Due to the unavailability of the original Spargo ash pumps, KSB pumps were selected as replacements. The system transports ash from two ash sumps via four pipelines (each supported by two-stage ash pumps) to the ash dam.

Description:

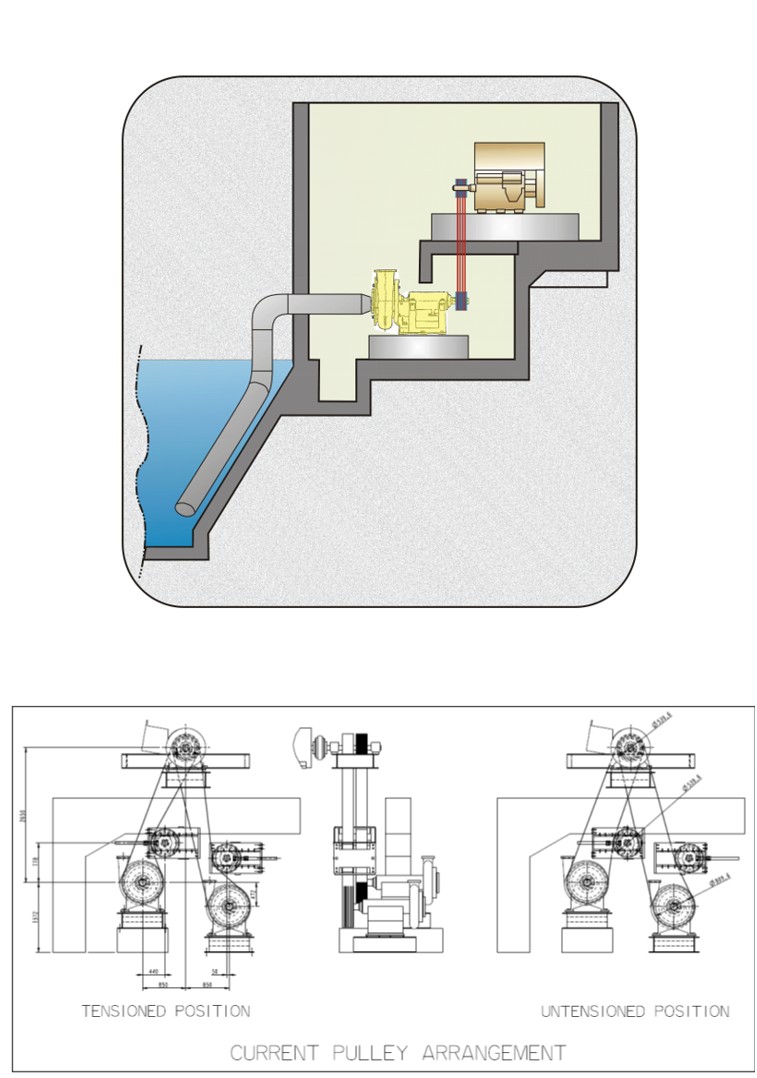

The ash handling system comprises eight ash pump units and four ash pipelines, designed to operate similarly to the original Camden Power Station configuration. The duty cycles were carefully calibrated within the pump drive design to regulate the ash flow rate to the ring feed system at the ash dam. MKDesigns contributed to the mechanical design, which included specifying and selecting the KSB ash pumps and designing the belt drive system to accommodate various duty points. Additionally, MKDesigns provided on-site support during the commissioning of the pumps, ensuring successful integration and operation of the upgraded ash handling system.