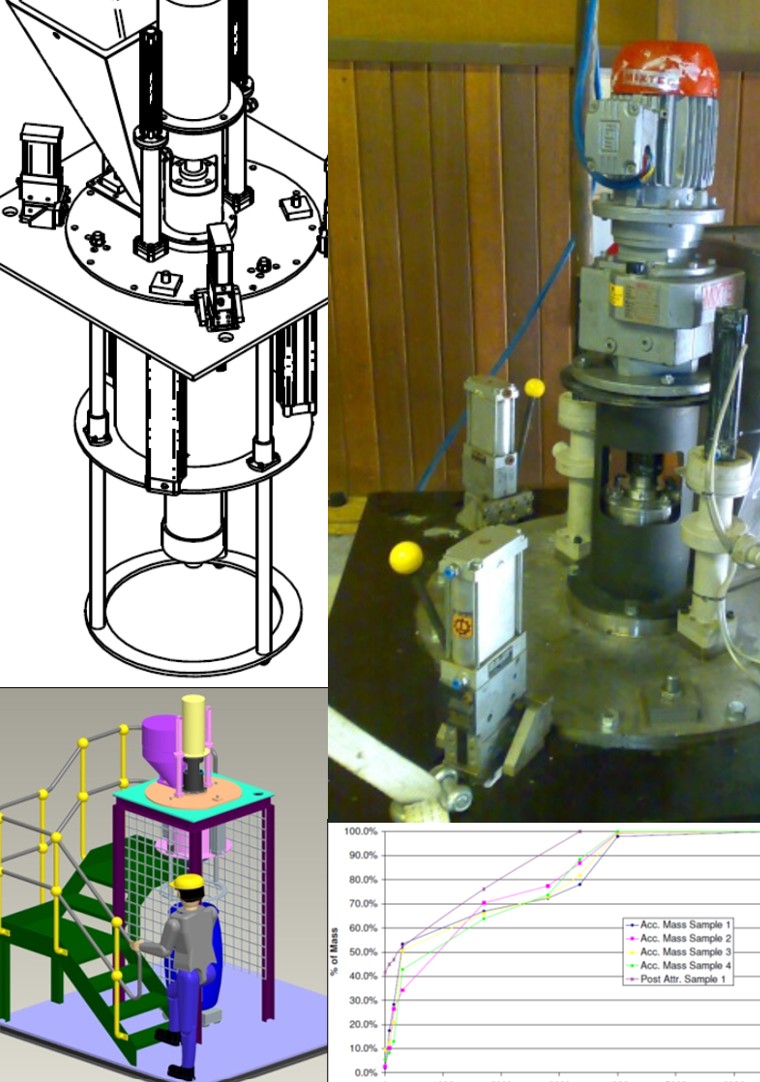

Attritioners

Project Details:

Total Value: $73 000

Year Completed: 2008

Duration: 12 months

Background:

MKDesigns was engaged to support the implementation of an attritioning process for a Micro-Diamond Laboratory. The objective was to introduce an intermediary sample processing step between crushing and primary dissolution to remove fine particles, thereby reducing the volume of acids required for processing.

Description:

The attritioning process was thoroughly investigated, tested, and optimized for the laboratory’s requirements. In the prototype plant, cyclones were previously employed to automatically deslime samples post-attritioning. A comprehensive study was conducted to evaluate the efficacy of cyclones as a desliming method, with a focus on achieving precise particle size separation. The attritioner was completely redesigned to accommodate a reduced sample size, enhancing operational efficiency. The integrated system, comprising the attritioner, an emptying mechanism, and the desliming process, was rigorously tested as a cohesive unit. Additionally, a granulometry study was performed to assess the effectiveness of the attritioning process, ensuring optimal performance and reliability for the laboratory’s operations.